Environmental Impact

Boundless Environmental Impact Analysis

The Boundless Impact Research and Analytics process employs traditional Life Cycle Analysis, selecting key environmental metrics customized for specific industries and integrating essential financial metrics to give the investor a clear picture of how their investment brings about environmental improvements.

Take a look at the highlights below or download the complete report

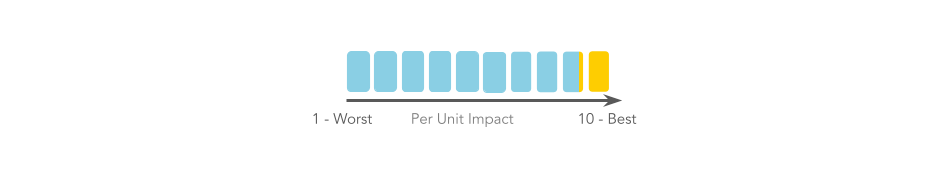

Vaagen Timbers Environmental Impact Score

Alignment With United Nations' Sustainable Development Goals

Environmental Highlights

Summarized below are the most relevant impact categories and codes that refer to the United Nations’ Sustainable Development Goals (SDGs). This section highlights the most important factors that explain how this technology impacts the environment and society.

Greenhouse Gas Emissions

Production of CLT flooring using Vaagen Timbers' product results in lower GHG emissions

from production, material sourcing, transportation, and floor design when compared with

GHG emissions from concrete slab flooring, slab on metal deck flooring, and wooden joist

flooring models. Vaagen Timbers’ CLT flooring has a GHG Footprint of 35 kilograms of CO2e

per meter squared of flooring. The analysis uses GWP 100 and assumes that the wood itself is

carbon neutral, meaning it is assumed that all carbon removed from the atmosphere is

eventually emitted to the atmosphere as CO2.

Industry, Innovation, and Infrastructure

Vaagen Timbers sources its products through sustainable forest management operations and harvesting small timber, allowing the larger trees to thrive while promoting the health of the forests. By sourcing wood locally and implementing sustainable forest management techniques, Vaagen Timbers aims to reduce both the impacts of forestry and the risk of spreading forest fires. Lowering the concentration of smaller trees in forests promotes forest health and decreases the spreadability of forest fires.

Responsible Consumption and Production

Vaagen Timbers is able to use less fossil fuel to produce its flooring than its concrete and steel-based competitors. Because concrete and steel are so heavy in comparison, they require more fossil fuel to assemble and transport than their wood-based alternatives. By relying on locally sourced lumber, Vaagen is able to reduce GHG emissions from the production and transportation of cement and metal while supporting the responsible use of local products.